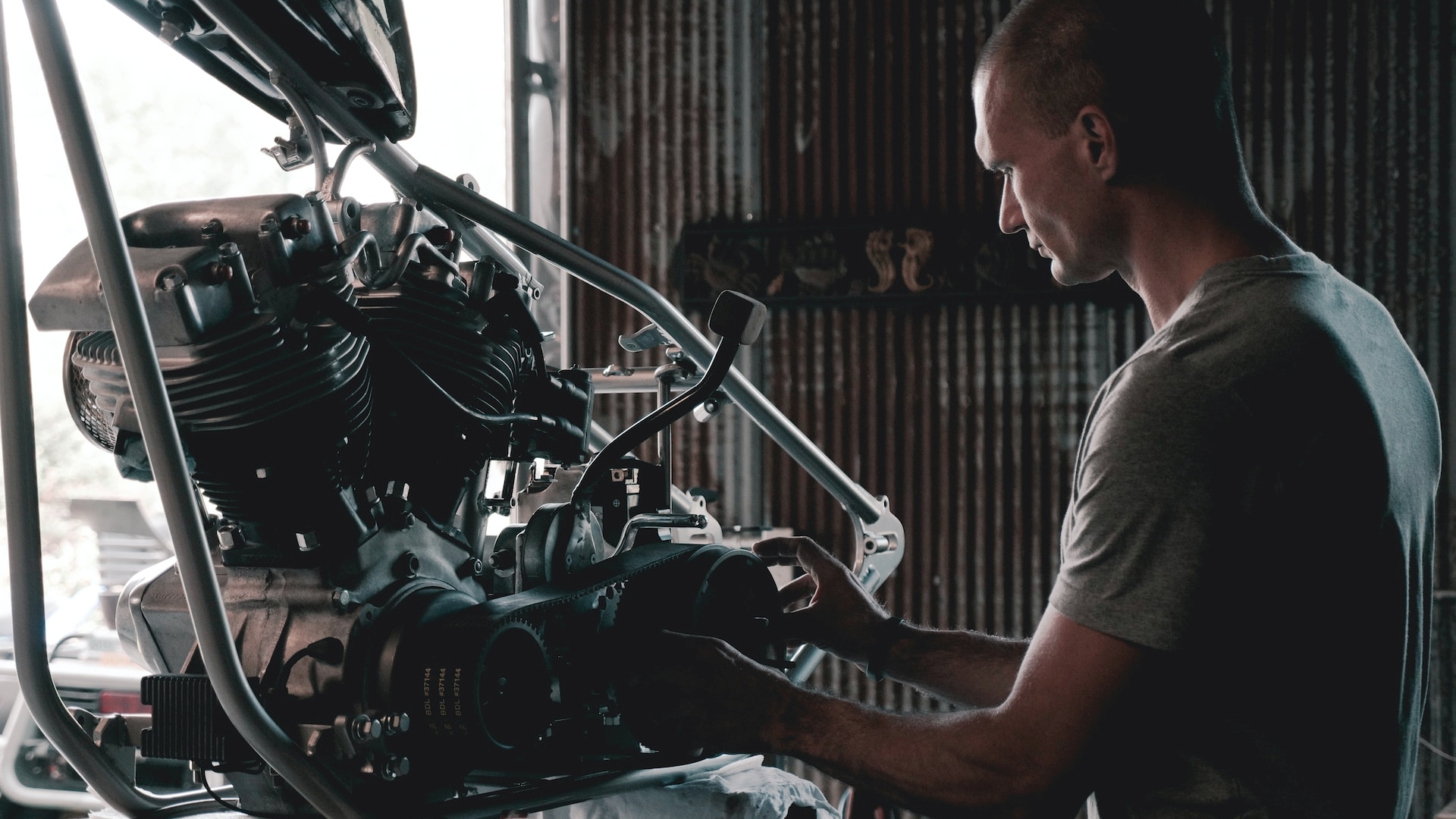

Whether you’re a mechanical engineer, an autoshop mechanic, or a do-it-yourselfer tinkering in the garage, preparing for and completing certain tasks can be time-consuming. Mechanical work preparation can involve anything from gathering specialty tools and ordering supplies to creating checklists and ensuring that your workspace is organized.

Therefore, let’s check the 7 essential tips that will effectively streamline your mechanical work preparation so that you complete your projects as quickly and efficiently as possible.

Establish a System for Tracking Parts and Components

Implementing a system for tracking these essential items is a smart move that can help streamline your production process and increase overall efficiency. By having a reliable tracking system in place, you’ll be able to quickly and easily locate specific parts and components when you need them – eliminating the frustration and delays that can result from misplaced or lost items.

Additionally, a tracking system can help you identify any issues with quality control, ensuring that all of your products meet your high standards.

Having Reliable Furniture and Fixtures

Investing in furniture and fixtures that are designed to increase efficiency can be a great way to streamline your mechanical work preparation.

For instance, you may want to look into purchasing an adjustable bench that allows for easier access to certain areas of the workspace, as well as specialized storage solutions for tools and components. Utilizing organization systems in multifunctional work benches can also help keep your workspace clean and clutter-free, enabling you to quickly locate the items that you need for any particular project. And that can be especially useful when you’re trying to work quickly and efficiently.

Create Checklists for Every Task

Checklists are an invaluable tool for any mechanical engineer or auto mechanic—they help keep your projects organized, eliminate unnecessary mistakes, and ensure that all of the necessary steps have been completed before moving on to more advanced tasks. Plus, having checklists in place during mechanical work preparation can help speed up the entire production process.

For instance, you may want to create a checklist for each step of the project that includes all of the necessary items and materials needed. This will ensure that nothing is overlooked, and help you work more quickly since everything needed for any particular task is already at your fingertips.

Utilize Technology to Streamline Your Processes

The right technology can play a key role in streamlining your mechanical work preparation. Automating certain processes, such as order placement and tracking, allows you to focus more on the tasks at hand rather than on tedious administrative duties. Additionally, utilizing software solutions to keep track of inventory and orders can simplify the entire process of ordering parts and components.

You may need to invest a bit of money in different hardware and software solutions, but the time savings and increased efficiency that they can bring to your production process will be well worth it.

Create Standard Operating Procedures for Each Type of Job

Having a set of standard operating procedures (SOPs) in place can help ensure that all tasks are completed properly and efficiently—which is essential for streamlining your mechanical work preparation. SOPs should include instructions on how to complete any particular task, as well as detailed safety protocols and quality control measures.

Let’s say, you have a specific process for inspecting parts before they’re shipped out. Having an SOP in place that outlines the exact steps and protocols for this task will be invaluable in helping ensure consistent quality control.

Prioritize Safety Above All Else

Safety should always be the number one priority in any mechanical engineering or auto repair workshop. Taking the necessary steps to ensure a safe working environment—such as having a well-stocked first-aid kit, implementing safety protocols, and providing appropriate personal protective equipment (PPE)—will go a long way toward keeping your staff safe and healthy.

Therefore, consider investing in the right safety equipment and systems to help ensure a safe working environment. Additionally, using a quality management system can help you identify any issues with quality control, ensuring that all of your products meet your high standards. This, in turn, will reduce the risk of any mishaps or accidents on the job.

Keep Track of Maintenance Records

When it comes to maintaining the equipment you rely on for your business, it’s essential to keep track of maintenance records for each piece. Not only does this ensure your equipment is operating efficiently, but it can also save you time and money in the long run. By documenting the maintenance performed on each asset, you can schedule routine upkeep, identify potential issues before they become costly problems, and track the lifespan of the equipment to plan for future replacements.

Additionally, having clear and organized records can demonstrate compliance with regulations and help with insurance claims.

Establishing and tracking parts and components, developing an accurate checklist for every job, utilizing technology to streamline processes, creating standard operating procedures for each type of job, and prioritizing safety are essential steps to streamlining your mechanical engineering preparation. Additionally, keeping track of maintenance records for each piece of equipment will help prolong its life and avoid costly repairs or replacements.

Making these routine processes as easy as possible will help increase efficiency to get each mechanical job done faster with fewer hassles.